Ultrasonic welding work

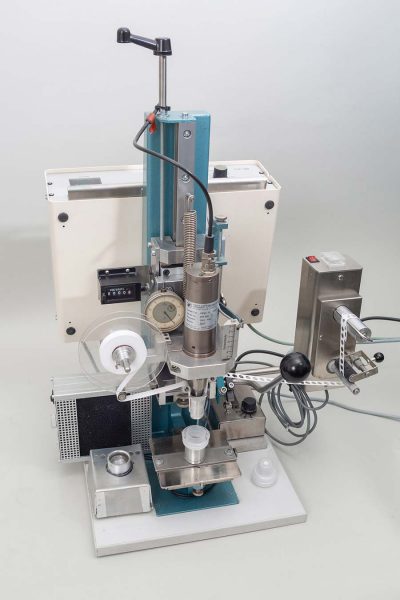

Various ultrasonic welding machines are available to us for a wide range of welding tasks. The in-house production from the workpiece holder to the sonotrode enables us to meet even complicated requirements.

Various ultrasonic welding machines are available to us for a wide range of welding tasks. The in-house production from the workpiece holder to the sonotrode enables us to meet even complicated requirements.

- Welding of cone screens - cuts of screen fabric are folded into a cone by the device, and the conical surface is welded with a specially designed sonotrode.

- Welding of polypropylene mesh panels - A ribbed sonotrode vibrating at very high amplitude is used to pierce through the top panel and the bottom side of the top mesh panel is welded to the top side of the bottom mesh panel.

- Weld screens into plastic parts, cutting out the screens at the same time.

- Weld gas-permeable PTFE membrane vents into threaded caps. The PTFE membrane is cut out of the strip and firmly welded at the same time.

- Weld cow ear tags. In this process, a 0.1 mm PVC film is welded onto small containers of PUR cow ear tag sets filled with desiccant. When attaching the ear tag, a genetic sample is cut out at the same time and pressed into the container with desiccant.

We also carry out welding work in-house that requires a high level of supervision, e.g. if the cutting edge of sonotrodes has to be reworked frequently or the work is carried out at long intervals so that it is not worthwhile for our customers to have their own machine.